- This topic is empty.

-

AuthorPosts

-

2025-08-21 at 11:48 am #4548

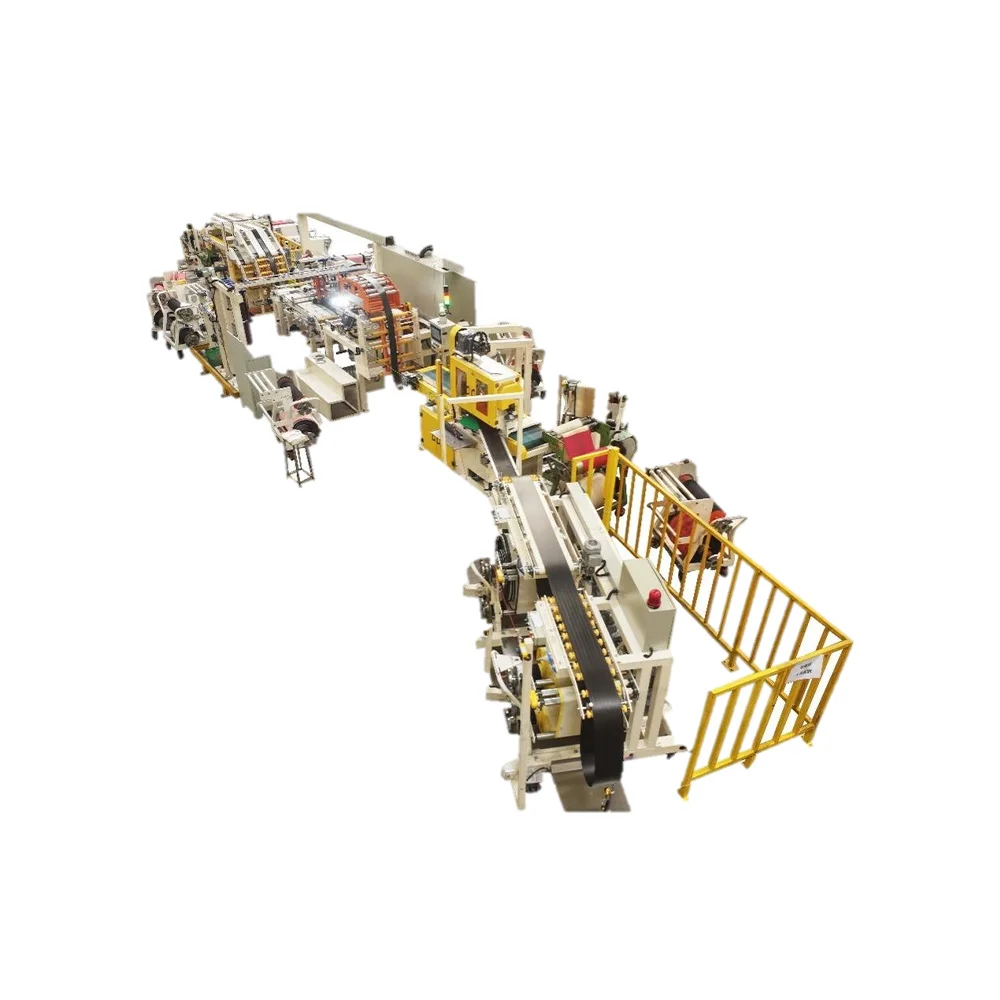

In modern industrial manufacturing, efficiency, precision, and durability are the pillars of productivity. Among the tools that embody these qualities, the steel belt cutting machine has emerged as an indispensable asset for enterprises looking to optimize their material processing lines. In this blog post, SONIWELL, a high performance tire manufacturing equipment seller, will share the features and applications of steel belt cutting machine for sale.

Understanding the Steel Belt Cutting Machine

A steel belt cutting machine is designed to cut steel belts or strips accurately and efficiently. Unlike traditional cutting methods that may cause excessive noise, misalignment, or slow operation, this advanced equipment integrates state-of-the-art mechanical and electronic controls to ensure precision and speed. Modern machines are engineered for durability, long-term performance, and seamless integration into automated production lines.

Patented Design: Innovation in Steel Belt Cutting Machine Technology

The patented product ZL202321077743.X represents a breakthrough in steel belt cutting technology. Its design focuses on reducing operational noise, enhancing cutting accuracy, and improving overall efficiency. With industrial operations demanding higher productivity without compromising safety, patented mechanisms like this provide companies with a competitive edge.

-

Noise Reduction: Traditional machines often operate at 95 dB, which can be disruptive in factory settings. The patented steel belt cutting machine significantly lowers noise levels to 70 dB, creating a safer and more comfortable environment for operators.

-

Precision Engineering: Every component is designed to maintain alignment during high-speed cutting, ensuring uniform results across all materials.

High Efficiency for Industrial Applications

Time is money in manufacturing. The steel belt cutting machine achieves remarkable throughput with a maximum cutting frequency of 25 times per minute, drastically reducing processing time compared to manual or semi-automated systems. This high efficiency is particularly beneficial for industries requiring rapid production cycles, such as automotive, packaging, and heavy machinery.

Grabbing Mechanism for Rapid and Accurate Operations

One of the core innovations of this machine is its grabbing mechanism, which utilizes a servo motor combined with a ball screw system. This setup ensures rapid and precise grabbing and overlapping of steel belts. The result is not only faster processing but also minimal material waste due to misalignment. Operators can rely on consistent performance, even during continuous production runs.

Continuously Adjustable Cutting Angle

Flexibility in cutting is crucial for customized applications. The machine’s cutting angle is continuously adjustable via an encoder, allowing precise cuts at various angles without manual recalibration. This feature is particularly useful for industries producing belts of different dimensions or requiring complex cutting geometries.

Optional Splitting Mechanism: Enhancing Productivity

For companies aiming to maximize output, the optional splitting mechanism is a game-changer. It offers:

-

Flexible width adjustment, accommodating belts of different sizes

-

Automatic overlapping, ensuring continuous material flow

-

Automatic material feeding roll, significantly reducing manual handling

Implementing the splitting mechanism can increase production efficiency by 2-3 times, making the steel belt cutting machine a high-return investment for manufacturing facilities.

Convenient Blade Replacement and Maintenance

Industrial downtime can be costly. The steel belt cutting machine addresses this with a convenient blade replacement system. The blade clearance is adjustable, enabling operators to maintain optimal cutting quality without prolonged machine stoppages. This design not only reduces maintenance time but also extends the lifespan of cutting components, lowering operational costs.

Low Noise Operation: A Safer and Quieter Work Environment

Noise pollution in factories is often overlooked but can affect worker safety and productivity. By reducing operational noise to 70 dB, this steel belt cutting machine not only complies with safety standards but also enhances worker comfort. A quieter environment enables better focus, reduces fatigue, and minimizes hearing-related risks, creating a more sustainable workplace.

Applications Across Industries

The versatility of the steel belt cutting machine makes it suitable for a wide range of industries:

-

Automotive: Cutting precision steel belts for timing belts, conveyor belts, and reinforced components

-

Packaging: Producing metal straps for heavy-duty packaging applications

-

Construction: Preparing steel reinforcement strips with exact measurements

-

Manufacturing: Cutting materials for industrial machinery and assembly lines

Its adaptability ensures that manufacturers can rely on a single machine to handle diverse cutting requirements without compromising efficiency.

Integrating Automation for Smart Factories

As Industry 4.0 continues to evolve, automation becomes increasingly critical. The steel belt cutting machine can be integrated into automated production lines, allowing:

-

Seamless connection with upstream and downstream machinery

-

Real-time monitoring and adjustments via PLC systems

-

Reduction of manual intervention, minimizing human error

The combination of automation and precision engineering positions this machine as a vital component in smart factories and high-volume production environments.

Conclusion

Investing in a steel belt cutting machine is not just about acquiring equipment—it is a strategic move to enhance industrial productivity, precision, and safety. With patented technology, high efficiency, noise reduction, adjustable cutting angles, optional splitting mechanisms, and convenient maintenance, this machine addresses the core needs of modern manufacturing.

Companies looking to stay competitive in fast-paced industrial sectors will find that the steel belt cutting machine delivers measurable improvements in efficiency, quality, and worker safety, making it a cornerstone of advanced production solutions.

http://www.soniwellgroup.com

SONIWELL -

-

AuthorPosts

- You must be logged in to reply to this topic.