- This topic is empty.

-

AuthorPosts

-

2026-01-14 at 11:01 am #6174

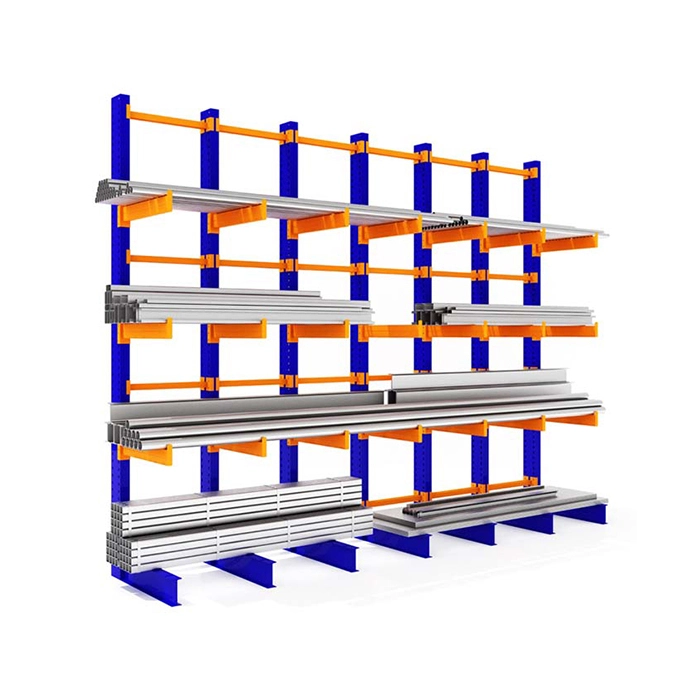

Maximizing storage efficiency while maintaining accessibility is a critical challenge for warehouses handling long bar goods, such as pipes, timber, rolls, and sheet materials. Cantilever racks offer a versatile solution for storing such items, enabling warehouses to optimize floor space, improve handling efficiency, and ensure safety. This practical guide explores the key considerations for designing efficient warehouse layouts with long bar goods cantilever racks, and highlights how choosing a reliable supplier like A-Plus ensures both quality and operational efficiency.

At A-Plus, we specialize in the design, manufacture, and installation of custom storage systems. Our expertise in high-strength, adjustable cantilever racks allows warehouses to handle heavy loads—up to 1,500 kg per arm—while providing flexibility in layout and arm configuration, either single-sided or double-sided.

1. Assessing Warehouse Requirements

Efficient cantilever rack design begins with a thorough analysis of warehouse needs:

-

Types of Goods: Identify the length, weight, and material type of the items to be stored. Long bar goods such as pipes, steel bars, or timber require racks with extended arms and reinforced supports.

-

Load Capacity Requirements: Calculate the maximum weight per arm to determine structural specifications. A-Plus cantilever racks can accommodate up to 1,500 kg per arm, suitable for most industrial applications.

-

Accessibility: Ensure aisles are wide enough for forklifts or manual handling equipment, but not so wide as to waste valuable storage space.

-

Storage Turnover: Consider whether goods are stored for short-term distribution or long-term inventory, as this affects rack height, arm spacing, and layout design.

Visual Suggestion: Table comparing typical long bar goods and recommended cantilever arm specifications.

Product Type Typical Length Recommended Arm Load Suggested Arm Height Spacing Timber 3–6m 500–1,500 kg Adjustable 300–600 mm Pipes 2–8m 400–1,500 kg Adjustable 250–500 mm Sheet Goods 1–4m 300–1,000 kg Adjustable 200–400 mm Rolls 1–3m 200–1,000 kg Adjustable 200–400 mm

2. Layout Design Principles

Designing a warehouse layout for cantilever racks involves balancing storage density, operational efficiency, and safety:

2.1 Single-Sided vs. Double-Sided Configuration

-

Single-Sided Racks: Ideal when one side is against a wall. Simplifies access for forklifts and reduces floor space usage.

-

Double-Sided Racks: Allows access from both sides, increasing storage density. Requires wider aisles but maximizes usable volume.

Tip: For narrow warehouses, single-sided racks along walls and double-sided racks in central aisles can optimize space and accessibility.

2.2 Arm Height and Spacing

-

Adjustable arm heights allow customization based on product dimensions, reducing wasted vertical space.

-

Proper spacing minimizes damage during loading/unloading while maintaining ergonomic reach for operators.

2.3 Aisle Planning

-

Forklift Movement: Aisle width must accommodate the turning radius of forklifts or reach trucks.

-

Safety Clearance: Include buffer zones at ends of racks to prevent collisions and ensure operator safety.

-

Flow Optimization: Arrange racks to match incoming/outgoing product flows, reducing travel time and improving productivity.

2.4 Zoning

-

Heavy Items Zone: Place high-weight items near the floor for easier handling.

-

Longer Goods Zone: Allocate longer arms and wider aisle spacing.

-

Fast-Moving Items: Position near loading docks for quick access.

3. Materials and Structural Considerations

Cantilever racks must be robust and durable for long-term warehouse use:

-

High-Strength Steel: Ensures arms can carry heavy loads without bending.

-

Powder Coating / Galvanization: Prevents corrosion, critical in humid environments or outdoor storage.

-

Arm Design: Tapered or reinforced arms prevent deflection under maximum load.

-

Base Stability: Adequate anchoring ensures rack stability, even when fully loaded.

Visual Suggestion: Diagram showing arm reinforcement, base anchoring, and weight distribution.

4. Cost Factors and ROI

The price of cantilever racks is determined by:

-

Material Quality: Higher-grade steel and surface treatment increase initial cost but extend lifespan.

-

Height & Length: Taller racks and longer arms require more steel and engineering.

-

Configuration: Double-sided racks and heavy-load arms cost more.

-

Installation: Professional installation ensures safety and compliance but adds labor costs.

ROI Considerations:

-

Increased storage density reduces warehouse expansion needs.

-

Optimized layouts improve operational efficiency and reduce handling time.

-

Durable racks reduce maintenance costs over time.

Example Table – Cost vs. Storage Efficiency

Rack Type Initial Cost Storage Capacity Payback Period Single-Sided 4-arm $5,000 12 pallets 2–3 years Double-Sided 6-arm $9,000 30 pallets 2–3 years Heavy-Duty 8-arm $12,000 40 pallets 3 years

5. Industry Applications

Cantilever racks for long bar goods are widely used in:

-

Construction Material Warehouses: Timber, steel bars, PVC pipes.

-

Sheet Metal Storage: Aluminum, steel, and other sheet goods.

-

Paper & Textile Rolls: Industrial rolls and packaging materials.

-

Plumbing & HVAC Warehouses: Pipes, conduits, and ductwork.

Visual Suggestion: Side-by-side layout diagram comparing single-sided vs. double-sided rack usage in a warehouse.

6. Maintenance and Safety Practices

Proper maintenance ensures long-term structural integrity and operational safety:

-

Regular Inspections: Check arm bolts, uprights, and base anchoring.

-

Load Compliance: Never exceed recommended weight per arm.

-

Floor Condition: Ensure level surfaces to prevent rack instability.

-

Operator Training: Forklift operators must follow safe loading/unloading procedures.

7. FAQ – Practical Questions for Warehouse Managers

Q1: What is the maximum load a cantilever arm can support?

A1: A-Plus cantilever arms can support up to 1,500 kg, depending on rack design.Q2: Can arm heights be adjusted after installation?

A2: Yes, arms are adjustable to suit changing storage needs.Q3: Which is better for my warehouse: single-sided or double-sided racks?

A3: Single-sided racks are space-efficient along walls, while double-sided racks maximize floor space in central aisles.Q4: How do I optimize aisle width?

A4: Consider the forklift turning radius and ensure enough clearance for safe operation.Q5: Are cantilever racks suitable for outdoor storage?

A5: With galvanized or powder-coated finishes, they are highly durable for outdoor conditions.

8. Conclusion

Designing an efficient warehouse layout with long bar goods cantilever racks requires a balance of storage density, safety, accessibility, and ROI. Key considerations include:

-

Material strength and durability

-

Adjustable arm height and spacing

-

Single-sided vs. double-sided configuration

-

Aisle planning for forklifts and operational flow

-

Supplier reliability and installation expertise

Choosing a trusted supplier like A-Plus ensures customized solutions, high-quality materials, professional installation, and long-term support, helping warehouses maximize storage efficiency and operational productivity while minimizing lifecycle costs.

http://www.aplusracking.com

Nanjing A-Plus Metal Products Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.